Amalungu e-Titanium alloy Icandelo leTrektara/Uomatshini beSanti yesinyithi/Intsimbi engoomatshini/Amalungu omatshini/eMoto woMzimba weCompressor

| Izinto eziphathekayo | IAluminiyam: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Intsimbi engatyiwa: SS201, SS301, SS303, SS304, SS316, SS430 njl. | |

| Intsimbi: intsimbi ethambileyo / intsimbi yekhabhoni kubandakanya 1010, 1020, 1045, 1050, Q690 njl. | |

| Ubhedu: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 njl. | |

| Ubhedu: C11000, C12000, C12000, C17200, C72900, C36000 njl. | |

| Iyaqhuba | EJamani Trumpf uphawu lweLaser cutter, umatshini wokucheba weCNC, umatshini wokugoba weCNC, |

| (CNC) umatshini wesitampu, uMshini weHyraulic, umatshini wokuwelda ohlukeneyo, iCNC iziko lomatshini. | |

| Umphezulu | I-Aluminiyam: iAnodization, iSandblast, iBrashi, ukupholisha, i-Electro-plating njl |

| Intsimbi yentsimbi: Ukumenyezwa, ukubrasha, ukuPasa, ukuqhushumba kweSandblasting, iElectro-plating | |

| Intsimbi: i-zinc plating, i-Nickel plating, i-Chrome plating, i-Powder Coating, ukupeyinta njl. | |

| Ubhedu kunye nobhedu: Ukubrasha, ukuhombisa njl | |

| Ukuchaneka | + - 0.1mm |

| Isicelo | Uloliwe, i-Auto, ilori, uNyango, oomatshini, izixhobo, i-Electronic, umbane njl |

I-Titanium luhlobo olutsha lwentsimbi.Ukusebenza kwe-titanium kuhambelana nomxholo wokungcola okufana nekhabhoni, i-nitrogen, i-hydrogen kunye ne-oxygen.Umxholo wokungcola kwi-iodide ye-titanium ecocekileyo ingaphantsi kwe-0.1%, kodwa amandla ayo aphantsi kwaye iplastiki iphezulu. i-thermal conductivity λ=15.24W/(mK), amandla okuqina σb=539MPa, ulwandiso δ=25%, ukushwabana kwecandelo ψ=25%, imodyuli yokuqina E=1.078×105MPa, ubulukhuni HB195.

Amandla aphezulu

Ubuninzi be-titanium alloy ngokubanzi malunga ne-4.51g / cm3, kuphela i-60% yentsimbi, kunye nezinye i-alloys ezinamandla kakhulu ze-titanium zidlula amandla amaninzi e-alloy structural steels. kunezinye izinto zentsimbi, ezinokuvelisa iinxalenye ezinamandla amakhulu eyunithi, ukuqina okulungileyo kunye nobunzima obulula.Amacandelo enjini ye-Aircraft, i-skeleton, isikhumba, i-fasteners kunye nezixhobo zokumisa zonke zisebenzisa i-titanium alloy.

Amandla aphezulu e-thermal

Ubushushu bokusetyenziswa bungamakhulu ambalwa edigri ngaphezulu kwe-alloyi ye-aluminium, isengagcina amandla afunekayo kwiqondo lobushushu eliphakathi, inokusebenza ixesha elide kumaqondo obushushu angama-450 ~ 500℃.Ezi ntlobo zimbini ze-titanium alloy kuluhlu lwe-150℃ ~ 500℃ zisenamandla athile aphezulu kakhulu, kunye nealloyi ye-aluminium kwi-150℃ amandla athile ehle kakhulu.Ubushushu bokusebenza be-titanium alloy bunokufikelela kwi-500℃, ngelixa i-alloy ye-aluminium ingaphantsi 200℃.

Ukumelana kakuhle nokubola

Ukumelana nomhlwa kwe-titanium alloy kungcono kakhulu kunoko kwentsimbi engatyiwayo kumoya omanzi kunye namanzi olwandle.I-Pitting corrosion, i-asidi, ukuxhathisa kwe-corrosion yoxinzelelo yomelele kakhulu;Inokumelana okugqwesileyo kokutya kwialkali, ikloridi, i-chlorine kwimveliso ye-organic, i-nitric acid. , i-asidi ye-sulfuric, njl.Kodwa ukuxhathisa ukubola kwe-titanium ekunciphiseni i-oksijini kunye ne-chromium medium ihlwempuzekile.

Ukusebenza kakuhle kobushushu obuphantsi

I-alloy ye-Titanium inokugcina iimpawu zayo zomatshini kwiqondo eliphantsi kunye ne-ultra-low.I-alloys ye-Titanium kunye nokusebenza kakuhle kweqondo lokushisa eliphantsi kunye nezinto eziphantsi kakhulu ze-interstitial, ezifana ne-TA7, inokugcina iplastiki ethile kwi-253℃.Ngoko ke, i-titanium alloy nayo ibalulekile. ubushushu obuphantsi impahla yesakhiwo.

Umsebenzi ophezulu weekhemikhali

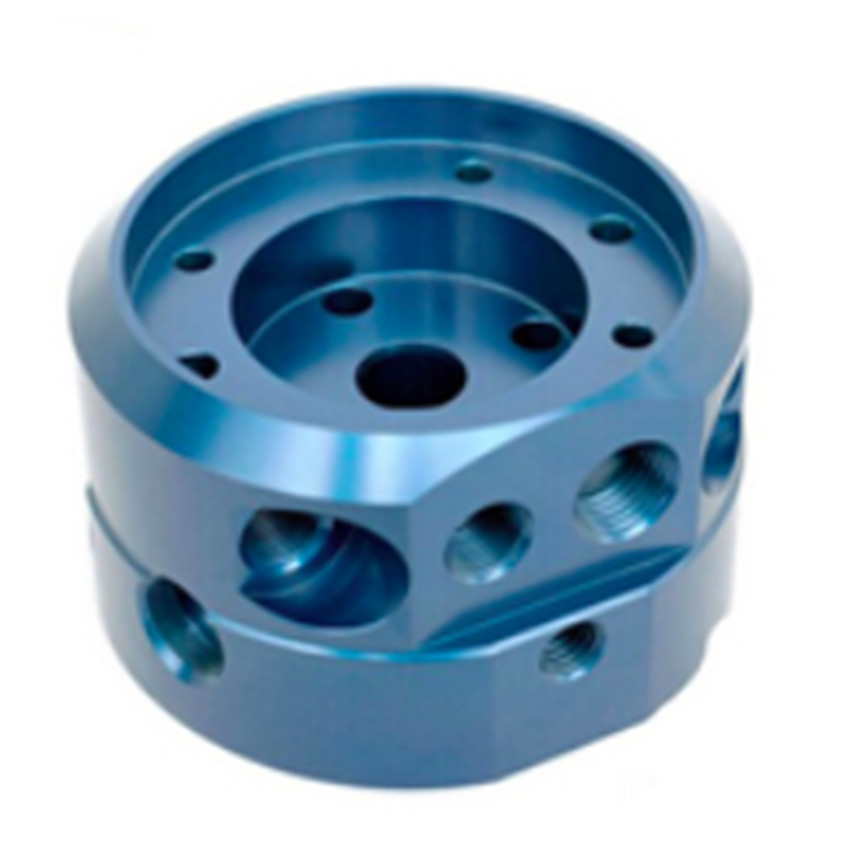

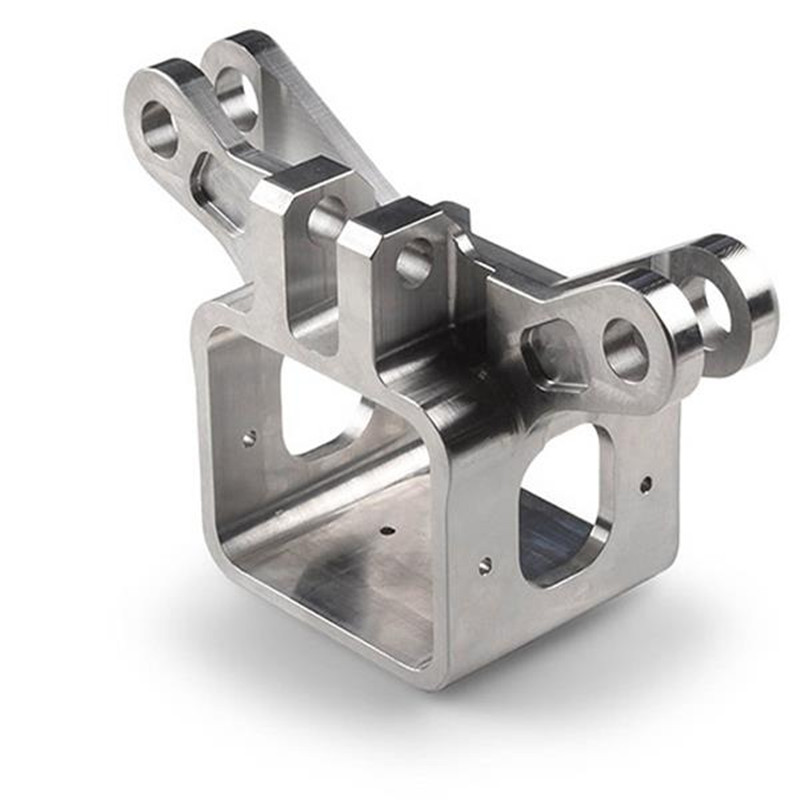

Iimveliso ze-Titanium alloy

Iimveliso ze-Titanium alloy

I-Titanium ine-chemical reaction enamandla kunye ne-O2, i-N2, i-H2, i-CO, i-CO2, umphunga wamanzi, i-ammonia kunye nezinye iigesi ezisemoyeni. iqondo lokushisa liphezulu, i-hard surface layer ye-TiN iya kwenziwa ngokusebenzisana kunye ne-N.Xa iqondo lokushisa lingaphezulu kwe-600 ℃, i-titanium ithatha i-oksijini kwaye yenza umaleko oqinileyo kunye nobunzima obuphezulu. Kwakhona ifom.Ubunzulu bomaleko obunzima kunye obunzima obuveliswa ngokufunxa igesi bunokufikelela kwi-0.1 ~ 0.15 mm, kwaye iqondo lokuqina li-20% ~ 30%. umphezulu.

Ukuqina kwe-thermal conductivity encinci

I-thermal conductivity ye-titanium (λ=15.24W/(m·K)) imalunga ne-1/4 yenikeli, i-1/5 yentsimbi, i-1/14 ye-aluminiyam, kunye ne-thermal conductivity ye-titanium eyahlukeneyo. i-alloys imalunga ne-50% ngaphantsi kwe-titanium.I-elastic modulus ye-titanium alloy imalunga ne-1/2 yentsimbi, ngoko ukuqina kwayo kubi, kulula ukuguqulwa, akufuneki kwenziwe ngentonga ebhityileyo kunye neengxenye ezinqabileyo ezinqabileyo, ukusika xa ukucutshungulwa komphezulu we-rebound kukhulu, malunga ne-2 ~ 3 amaxesha ensimbi engenasici, okubangela ukukhuhlana okukhulu, ukunamathela, ukunxiba okuncamathelayo kwindawo yesixhobo.