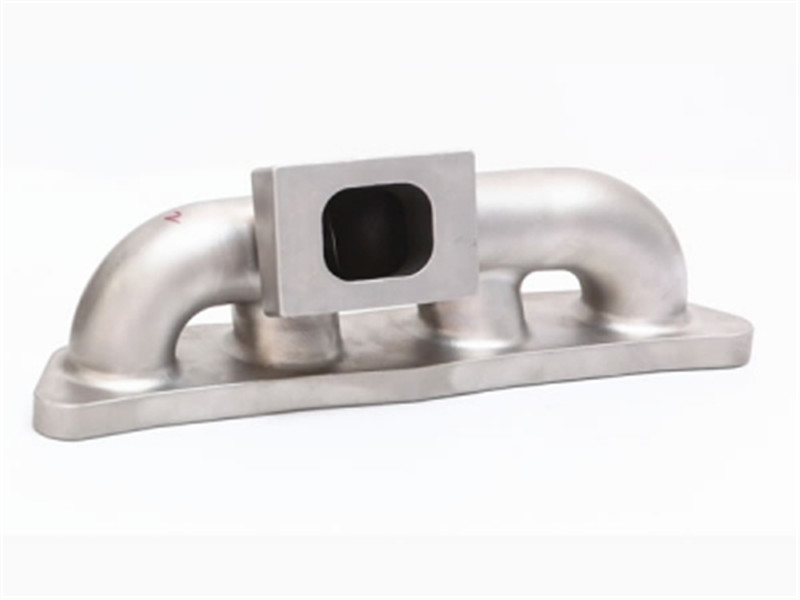

Ukuphoswa kwentsimbi ye-OEM kwi-Wax elahlekileyo

Ingcaciso yeMveliso

Iziseko zeMetal Casting

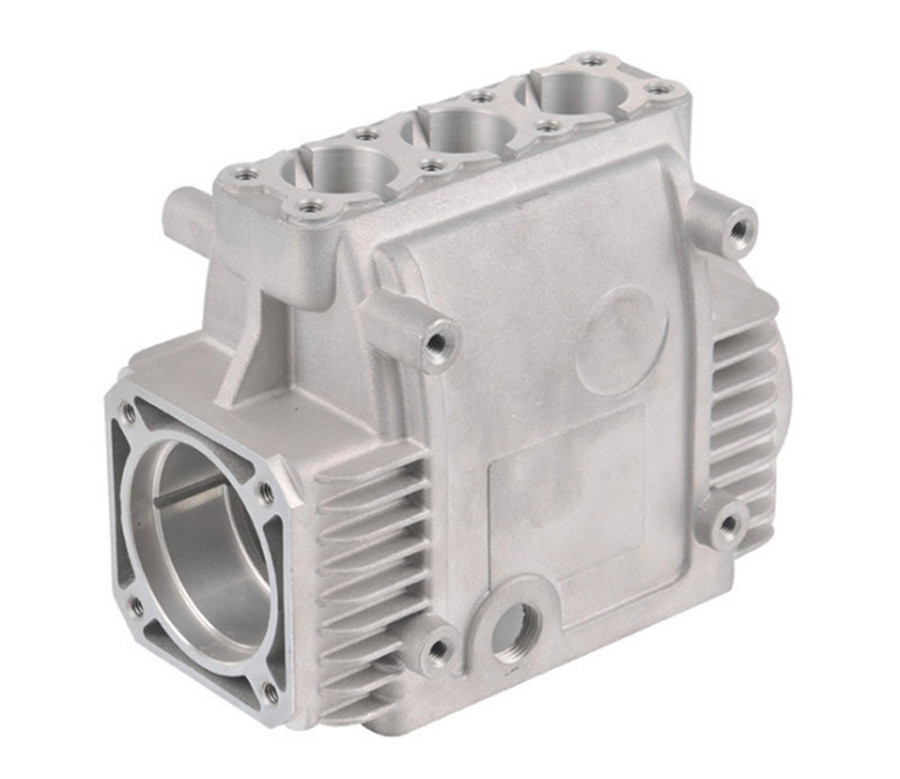

Utyalo-mali lwesinyithi lunika ithuba lokuvelisa iintlobo ngeentlobo zeemilo eziphantse zingenasiphelo ukusuka phantse kuyo nayiphi na ingxubevange.I-Metal Casting ikwavumela ukongezwa kweempawu ezingasikelwanga mda ezinokudityaniswa kanye kubumba.

Xa kusenziwa iinxalenye ezintsonkothileyo, ezintsonkothileyo okanye iiassemblies, abukho obunye ubuchule bokuyila obunokulingana nexabiso eliphezulu lokusebenza kotyalo-mali lwesinyithi.

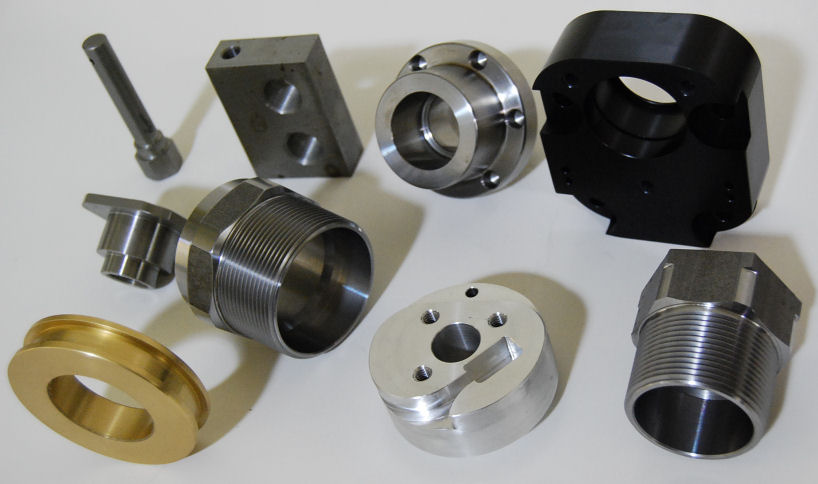

Inkululeko yoyilo kunye noKuguquguquka

Ngaphezulu kwe-120 ezahlukeneyo ze-ferrous kunye ne-non-ferrous casting alloys ezikhoyo, i-Mingda inokuvelisaiintsimbi zentsimbiusebenzisa phantse nasiphi na isinyithi utyalo mali unlimited izicelo casting.Inkqubo yokuphosa utyalo-mali yesinyithi ininzi kakhulu kwaye ivelisa uluhlu olubanzi lweendibano zetsimbi zoluhlu lwamashishini.Utyalo-mali lwamacandelo entsimbi lubonelela ngobuchule bokuguquguquka koyilo lwemveliso entsonkothileyo, izakhiwo ezinenxalenye enye.

Iindleko zezixhobo ezisezantsi

Isixokelelwano sokuqala sokubumba se-wax esisetyenziselwa ukuvelisa iipateni zokuphosa isinyithi, i-avareji yomthamo wenxalenye, ihlala iphantsi kwezinye iindleko zezixhobo zokuvelisa.I-Mingda ivelisa iimbumba zayo

endlwinikwaye uzigcine simahla ubomi benkqubo.Ngokumalunga neenzuzo zexesha elide isixhobo esisemgangathweni sivelisa inxalenye esemgangathweni kwaye ngoko kuya kuba neendleko eziphezulu kwixesha elide.I-Mingda isebenzisa iteknoloji yamva nje yokuqinisa isoftware kunye nezenzo ezintsha zokuqinisekisa iipateni ezingaguqukiyo nezichanekileyo zewax ukwenza iinxalenye zakho zentsimbi.

Ukuthembeka

Ukuthembeka kubunjineli kuyo yonke indawo yentsimbi.Inkqubo yotyalo-mali yesinyithi kwi-Aero Metals ilandelwa ngenkqubo ye-ERP ye-state-of-art, ukubeka iliso kwimveliso yethu ukuze kuqinisekiswe umgangatho kunye nokuchithwa kwesinyithi okuthembekileyo ngokubeka kunye nokulawula inkqubo.Sikwabambelela kwiinkqubo zethu zomgangatho we-ISO eziqinisekisiweyo ukuhambisa ukuphindaphinda ukusuka kwiqashiso ukuya kwiqashiso.

Ulawulo loNyamezelo oluqinileyo

I-Mingda iyakwazi ukubamba +/- 0.003 ″ kwezinye iimeko, nangona kunjalo, +/- 0.005″ ngumgangatho oqhelekileyo wotyalo-mali lwesinyithi olindele ukunyamezela.Njengoko kwiindlela ezininzi zanamhlanje, ixabiso lenxalenye liya kunyuka njengoko ukunyamezela kwenxalenye kuya kuba nzima kwaye iimfuno zokuhlola ziba nzima.Ukunyamezela okuqinileyo ngaphaya kwemigangatho yotyalo-mali oluqhelekileyo lufezekiswa ngeenkqubo zokuphoswa emva kokuphoswa okunje ngokuqondisa (kushushu okanye kubanda), i-coining, broaching, kunye ne-machining.

UkuNcitshiswa kweNkunkuma

I-Metal investment casting iveliswa kwiipateni ze-wax, ezibuyiselwayo, zicociwe, kwaye ziphinde zisetyenziswe ixesha kunye nexesha kwakhona.Ipateni ye-wax isetyenziselwa ukufaneleka kwangaphambili ukuphosa isinyithi kwinxalenye, enciphisa isinyithi sentsimbi.Okubaluleke ngakumbi, inkqubo yokuphosa utyalo-mali lwesinyithi ivelisa iinxalenye kumnatha- okanye kufuphi ne-net shape, enciphisa kakhulu, okanye iphelisa, inkunkuma yesibini yomatshini.Nasiphi na intsimbi yokuphosa intsimbi inokuphinda inyibilike, ivavanywe, kwaye igalelwe kwakhona.Ukwenziwa kwesinyithi yinkqubo eluhlaza kakhulu kunye ne-eco-friendly.

Uyilo oloNgezelelwe ixabiso

Ngokungafaniyo nezinye iindlela ezininzi zokuvelisa, i-casting investment castings ayifuni nayiphi na idrafti.Injineli yokuyila ikhululekile ukubandakanya iimpawu ezinje nge-under-cuts, iilogo, amanani, kunye noonobumba kwicandelo lokuphosa isinyithi.Ukongeza, ngemingxunya, iindawo zokubeka, imingxuma eyimfama, i-splines yangaphandle nangaphakathi, iigiya, kunye neeprofayili zentambo zinokuphoswa ukunciphisa ixesha lomatshini wesibini kunye nexabiso lenxalenye epheleleyo.Sitsalele umnxeba kwaye siya kukuvuyela ukudibana nawe kwiprojekthi yakho kwaye sinikezele ngoncedo loyilo lwenkqubo yokwenziwa kotyalo-mali lwesinyithi.

Iimveliso zibonisa

Inkqubo

Umzi-mveliso wethu