OEM Custom Grey Iron Casting

Ingcaciso yeMveliso

Intsimbi engwevu, okanye intsimbi engwevu, luhlobo lwezinto eziphathekayo zentsimbi kunye ne-graphic microstructure.Silubiza olu hlobo lwezinto ezingwevu zentsimbi ngenxa yombala ongwevu wokwaphuka.Kuba igraphite ithambisa isikwe kwaye iqhekeze iitshiphusi, intsimbi engwevu yintsimbi eqhelekileyo ngenxa yexabiso eliphantsi kunye nokusebenza kakuhle.Ngaphandle koko, ngenxa yokuba i-graphite flakes i-self-lubricate, ikwanayo ne-galling elungileyo kunye nokumelana nokunxiba.

I-iron engwevu nayo inokuncipha kokuqina okuncinci kunezinye iintsimbi ezityhidiweyo ngenxa ye-graphite microstructure.Ukuphosa, into ye-silicon inokukhuthaza ukuxhathisa okulungileyo kokubola kunye nokwandisa umbane xa uphosa.Intsimbi engwevu ngokuqhelekileyo ithathwa njengelula ukuwelda.Xa kuthelekiswa nezinyeiintsimbi, intsimbi engwevu inamandla aphantsi kunye ne-ductility;yiyo loo nto impembelelo kunye nokuxhathisa ukothuka kolu hlobo lwezinto eziphathekayo luphantse lungabikho.

ABanga iGrey Iron esetyenziswa Rhoqo

| Intsimbi eNgwevu | Ubunzima bodonga/mm | C | Si | Mn | P≤ | S≤ |

| HT150 | <30 | 3.3-3.5 | 2.0-2.4 | 0.5-0.8 | 0.2 | 0.12 |

| 30-50 | 3.2-3.5 | 1.9-2.3 | 0.5-0.8 | 0.2 | 0.12 | |

| >50 | 3.2-3.5 | 1.8-2.2 | 0.6-0.9 | 0.2 | 0.12 | |

| HT200 | <30 | 3.2-3.5 | 1.6-2.0 | 0.7-0.9 | 0.15 | 0.12 |

| 30-50 | 3.1-3.4 | 1.5-1.8 | 0.8-1.0 | 0.15 | 0.12 | |

| >50 | 3.0-3.3 | 1.4-1.6 | 0.8-1.0 | 0.15 | 0.12 | |

| HT250 | <30 | 3.0-3.3 | 1.4-1.7 | 0.8-1.0 | 0.15 | 0.12 |

| 30-50 | 2.9-3.2 | 1.3-1.6 | 0.9-1.1 | 0.15 | 0.12 | |

| >50 | 2.8-3.1 | 1.2-1.5 | 1.0-1.2 | 0.15 | 0.12 |

Kwisiseko sethu, sinokwenza iintsimbi ezingwevu kwiindidi ezimbini ezingezantsi:

Ukuphosa amagwebu alahlekileyo: Yokuphelautyalo maliinkqubo yamacandelo entsimbi etyhidiweyo, enenzuzo eninzi ukuvelisa utyalo-mali oluncinci lwentsimbi engwevu, njengeendleko zokungunda ezigciniweyo, ukunciphisa umjikelo wemveliso kunye nokuphucula ukusebenza kakuhle kwemveliso.Ngenkqubo yokuphosa amagwebu elahlekileyo, sinokunceda abathengi bethu bafumane iimveliso ezichaneke kakhulu ngokugqitywa komphezulu ogqwesileyo, kunye nokusebenza kancinci komatshini kuya kwenziwa.

I-Resin Sand Casting: Inkqubo ephambili yokugalelwa kwesanti yeesanti ezincinci neziphakathi.Xa kuthelekiswa nezinye iinkqubo zokugalela isanti, ukugalelwa kwentlabathi yeresin yindlela echanekileyo yokuphosa ekufutshane nokuphosa utyalo-mali.Njengokuqina okulungileyo kwesanti yentlaka kunye nokomelela okuphezulu kokungunda kwesanti xa kusenziwa kwangethuba, emva koko sinokuwuphelisa ngokufanelekileyo umngxuma wokushwabana, iziphene zokushwabana kwentsimbi engwevu.

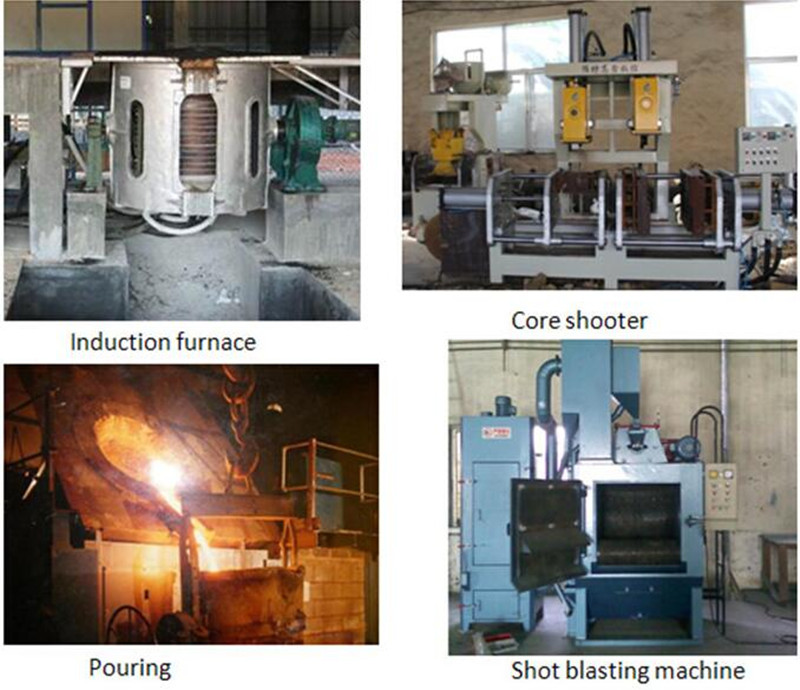

Izixhobo zokuphosa